Med folkehelse og sikkerhet som en topprioritet i hverdagen vår, blir automatiske dørlåser stadig mer populære, og disse låsene må ha sofistikert bevegelseskontroll. Miniatyrpresisjonsteppermotorerer den ideelle løsningen for dette kompakte og sofistikerte designet. Automatiskdørlåserhar eksistert en stund, først i kommersielle områder på hoteller og kontorer. Med økningen i antall smarttelefonbrukere og spredningen av smarthusteknologi, har automatiske løsninger for boligerapplikasjoner for dørlåshar også blitt populære. Det er tekniske forskjeller mellom kommersielle og private brukere, som bruk av batterier kontra elektronisk tilkobling og RFID kontra Bluetooth-teknologi.

Den tradisjonelle låsen krever at nøkkelen settes inn i låsesylinderen for å låse/låse opp den ved å vri den manuelt. Fordelen med denne metoden er at den er ganske sikker. Folk kan forlegge eller miste nøkler, og prosessen med å bytte låser/nøkler krever bruk av verktøy og ekspertise. Elektroniske låser er mer fleksible når det gjelder adgangskontroll og kan ofte enkelt endres og oppdateres via programvare. Mange elektroniske låser tilbyr både manuelle og elektroniske låskontrollalternativer, noe som gir en mer robust løsning.

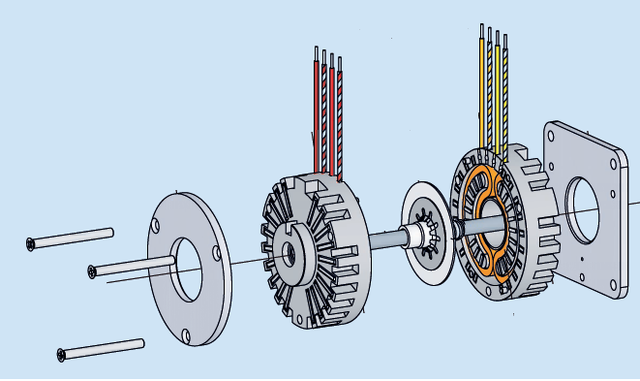

Steppermotorer med liten diameter for kompakte elektroniske låser er ideelle for løsninger med størrelsesbegrensninger og presis posisjonering. Motorteknikk og proprietære magnetiseringsteknologier har drevet utviklingen av steppermotorer med den minste diameteren som er tilgjengelig for øyeblikket (3,4 mm ytterdiameter). Avanserte magnetiske og strukturelle analyseteknikker brukes for å optimalisere design og materialer for den begrensede tilgjengelige plassen. En av de viktigste beslutningene for miniatyrsteppermotorer er motorens trinnlengde, som avhenger av den spesifikke oppløsningen. De vanligste trinnlengdene er 7,5 grader og 3,6 grader, som tilsvarer henholdsvis 48 og 100 trinn per omdreining, hvor steppermotorer har en trinnvinkel på 18 grader. Med en full trinndrift (2-2 faset eksitasjon) roterer motoren 20 trinn per omdreining, og den vanlige stigningen til skruen er 0,4 mm, slik at en posisjonskontrollnøyaktighet på 0,02 mm kan oppnås.

Steppermotorer kan ha en girreduksjonsgir, som gir en mindre stegvinkel, og et reduksjonsgir som øker det tilgjengelige dreiemomentet. For lineær bevegelse er steppermotorer koblet til skruen via en mutter (disse motorene kalles også lineære aktuatorer). Hvis den elektroniske låsen bruker en girreduksjonsgir, kan skruen beveges med presisjon selv med stor helling.

Inngangsdelen av steppermotorens strømforsyning kan ha forskjellige former, for eksempel FPC-kontakter, kontaktterminaler kan sveises direkte til PCB-en, skyvestangen på utgangsdelen kan være en plastglider eller en metallglider, og et visst utvalg av tilpassede glidere i henhold til låsens vandringskrav. På grunn av den lille steppermotoren og tynne skruer er den bearbeidede gjengelengden begrenset, og låsens maksimale vandring er vanligvis mindre enn 50 mm. Vanligvis har steppermotoren en skyvekraft på omtrent 150 til 300 g. Skyvekraften varierer avhengig av drivspenning, motormotstand, etc.

Konklusjon

Med forbrukernes interesse for produkter med lav margin og diskrete løsninger, kan miniatyr-trinnmotorer håndtere denne krympende størrelsen. I tillegg til den kompakte formfaktoren er trinnmotorer enklere å kontrollere, spesielt for presis posisjonering og krav til lavt dreiemoment, som automatisk låsing. For å oppnå samme funksjonalitet krever andre motorteknologier tillegg av Hall-effektsensorer eller komplekse mekanismer for posisjonstilbakemeldingskontroll. Trinnmotorer kan drives med enkle mikrokontrollere, noe som kan avlaste designingeniører fra bekymringene for altfor komplekse løsninger.

Publisert: 25. november 2022